Dlw Varanasi Summer Training Report Pdf

• A SUMMER FIELD TRAINING REPORT AT DIESEL LOCOMOTIVE WORKS VARANASI Submitted To Faculty Of Engineering And Technology, Chandra SekharAzad University Of Agriculture And Technology, Kanpur In partial fulfillment of the requirement for the award of degree of BACHELOR OF TECHNOLOGY IN MECHANICAL ENGINEERING BY SHAILESH SHUKLA CT –1674/09 Baba Saheb Dr. Bhim Rao Ambedkar College Of Agricultural Engineering And Technology, Etawah-206001 (Chandra Sekhar Azad University Of Agriculture And Technology, Kanpur) • ACKNOWLEDGEMENT I would sincerely like to thank the employees and the officers of DLW, VARANASI for their help and support during the vocational training.

~best pdf~ - Download PDF/ePub eBook Summer Training Report Dlw Summer Training Report Dlw [PDF] SUMMER TRAINING REPORT DLW. Dlw summer training report download Hi i m stuta I woluld like to have this pdf report of DLW training for 6. Dlw varanasi summer training report for.

Despite their busy schedules, they took time out for us and explained to us the various aspects of theworking ofthe plant from the production shops. I would sincerely like to thank Mr. Sudhir Sinha (CWI /TTC) and Mr. Ajay Kumar(JE/HWS), Mr. Vipin Srivastava(JE/HWS), Mr. Arvind Kumar(JE/HMS),Er. Ravi Gupta(SSE/HMS) who was instrumental in arranging the vocational training at DLW Varanasi, and without whose help and guidance the training could not have materialize.

I express my deep sense of gratitude to Mr. S.P.Singh (Principal, TTC) for given me such a great opportunity. • PREFACE The objectives of the practical training are to learn something about industries practically and to be familiar with the working style of a technical person to adjust simply according to the industrial environment. It is rightly said practical life is far away from theoretical one. We learn in class room can give the practical exposer real life experience no doubt they help in improving the personality of the student, but the practical exposure in the field will help the student in long run of life and will be able to implement the theoretical knowledge. As a part of academic syllabus of four year degree course in Mechanical Engineering, every student is required to undergo a practical training.

I am student of third year mechanical and this report is written on the basis of practical knowledge acquired by me during the period of practical training taken at Diesel Locomotive Works, Varanasi. • CONTENTS [1].Introduction to DLW. Heavy Welding Shop. Light Machine Shop. Airplane Games For Pc. Truck Machine Shop. Machine Shop. Bibliography • INTRODUCTION TO DLW Diesel Locomotive Works (DLW) is a production unit under the ministry of railways.

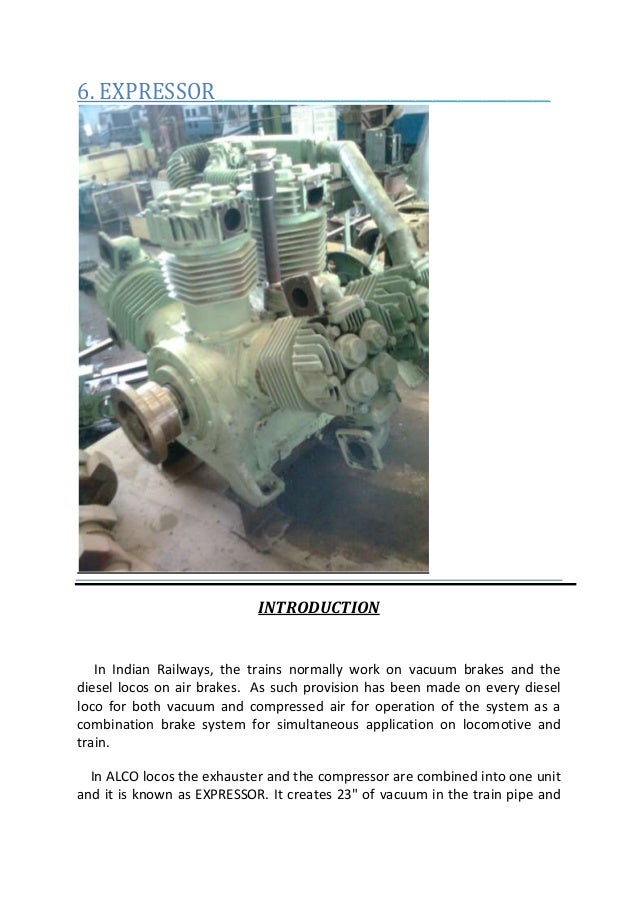

This was setup in collaboration with American Locomotive Company (ALCO), USA in 1961 and the first locomotive was rolled out in 1964. This unit produces diesel electronic locomotives and DG sets for Indian railways and other customers in India and Abroad. Subsequently a contract for transfer of technology of 4000 HP Microprocessor Controlled AC/AC Freight (GT 46 MAC) / passenger (GT 46 PAC) locomotives and family of 710 engines has been signed with electro motive division of GENERL MOTORS of USA for manufacture in DLW. The production of these locomotives has now started and thus DLW is the only manufacturers of Diesel Electric Locomotives with both ALCO and General Motors technologies in the world. • Brief History: Set up in 1961 as a green-field project in technical collaboration with ALCO/USA to Manufacture Diesel Electric Locomotives. First locomotive rolled out and dedicated to nation in January, 1964.

Transfer-of-Technology agreement signed with General Motors/ USA in October, 95 to manufacture state-of-the-art high traction AC-AC diesel locomotives. A flagship company of Indian Railways offering complete range of flanking products in its area of operation. State-of-the art Design and Manufacturing facility to manufacture more than 150 locomotives per annum with wide range of related products viz. Wan Miniport Pppoe Driver For Windows 7. Components and sub-assemblies.

Unbeatable trail-blazing track record in providing cost-effective, eco- friendly and reliable solutions to ever-increasing transportation needs for over three decades. Fully geared to meet specific transportation needs by putting Price-Value- Technology equation perfectly right. A large base of delighted customers among many countries viz. Sri Lanka, Malaysia, Vietnam, Bangladesh, Tanzania to name a few, bearing testimony to product leadership in its category. Backgammon By Paul Magriel Pdf Printer. SALIENT FEATURES: Annual production capacity 125 Locomotives Annual turn-over (Rs) 5000 million Total number of staff 7223 • Workshop land 89 Hectares Township area 211 Hectares Covered area in shops 86300 m2 Covered area of other service buildings 73700 m2 Electrical power requirement 3468 KVA (Average maximum demand) Electrical energy consumption (units/year) 19.8 million Standby power generation capacity 3000 KW PRODUCT OF DLW: DLW is an integrated plant and its manufacturing facilities are flexible in nature.